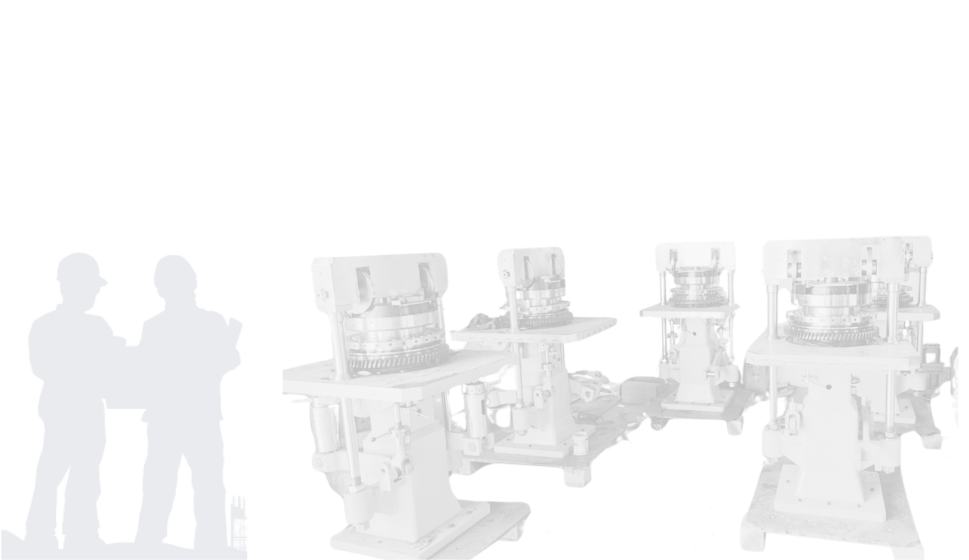

Automatic Ropp Capping Machine

KI ROPP Cap sealing machine is designed to seal ROPP caps for various sizes of the bottles fed on a continuous line. Change parts are available for different size of cap sand bottle diameter. The machine is fully automatic and its operation is very simple. The bottles are fed by means of a S.S. Slat conveyor to the pickup point of cap-vibrator chute A cap is picked up by the bottle and the star wheel carries the bottle under the sealing head. The complete head assembly moves down and perfect closure is achieved by the threading and skirting rollers.

The movement of the bottles is arranged from left to right on the conveyor. Main drive motor 1.5H.P. 415 volts and suitable panel board mounted on machines Bottle size tolerance required for the machine & ± / 0.5 mm. for bottle dia. & height. The output cap of machine is 20 to 30 bottles/min. The feed container moving on conveyor belt are feed into an in feed star wheel through in-feed worm, star wheel bringing the container below the sealing head in the subsequent indexing part, meanwhile the bottle pick up a cap from the delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of threading & sealing.